Every Flamery grill is crafted by us right here in our North Yorkshire factory. Nestled within a larger manufacturing business, Flamery benefits from continuous investments in state-of-the-art machinery by our parent company, Rack Systems. This dedication to quality and innovation not only ensures the superiority of our products but also guarantees that your Flamery grill is impeccably made here in the UK. Explore the processes our grills undergo below to learn more.

The Materials

We use a mixture of high quality, heavy grade mild and stainless steel across our grills. The body of the grills are manufactured from 2.5mm Mild Steel. These panels are powder coated using a high temperature coating that should harden further with use. Cooking surfaces and the inner linings of the lids and doors are made from stainless steel, ensuring they wear well over time .

Some discolouration is normal given the high temperatures the grills operate at. This will not affect the functionality of your BBQ.

Stainless steel cooking surfaces should be seasoned well before use. This process causes some discolouration to the shiny, new surfaces. This patina is a good thing and protects the steel from corrosion and also creates the non-stick surface we're looking for.

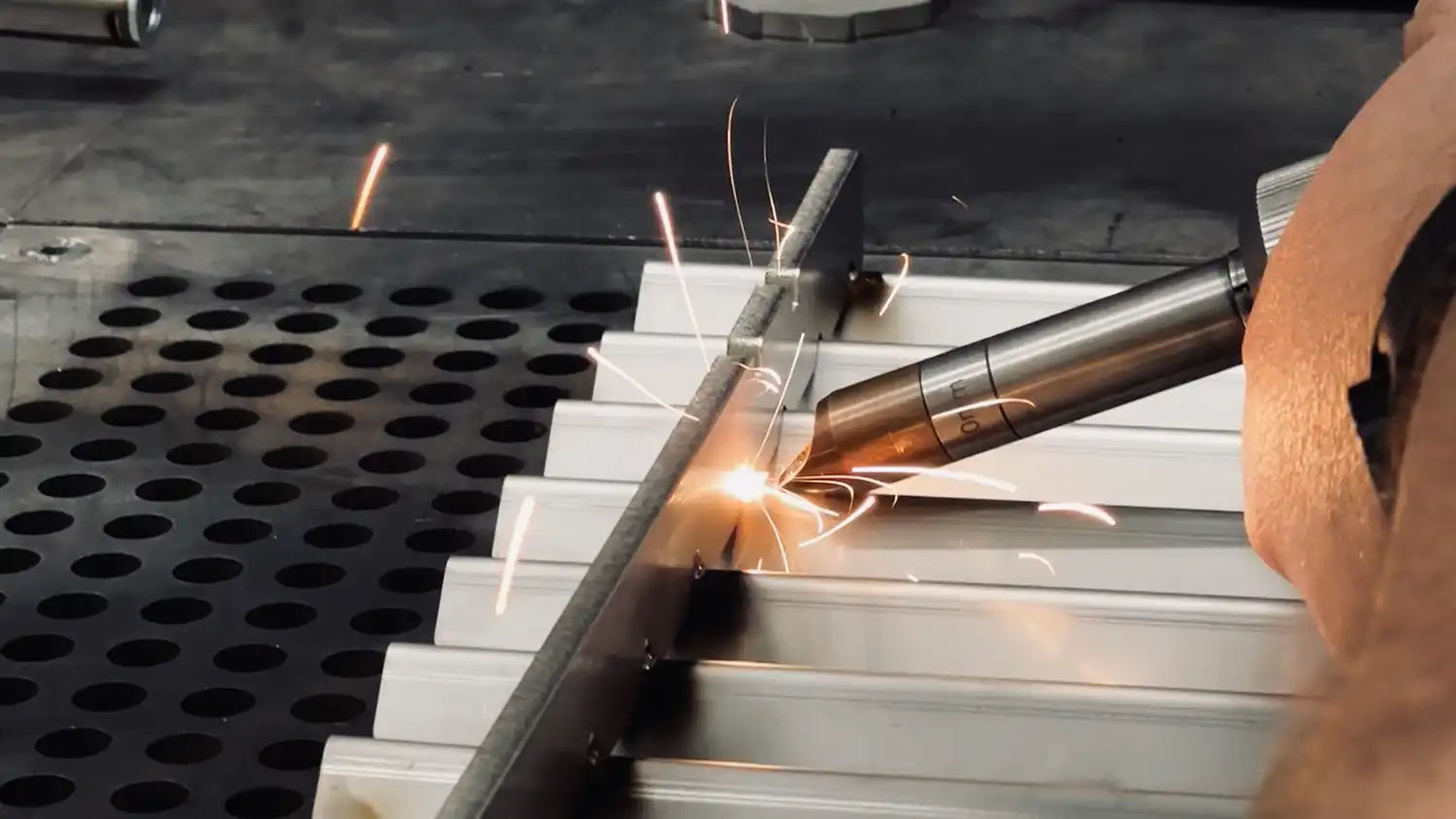

Laser Cutting

The manufacturing process begins with cutting both tube and sheet steel parts using advanced fibre lasers.

Our flatbed fibre laser ensures precision by expertly cutting all sheet steel components from full sheets of high-quality material.

Similarly, our cutting-edge tube lasers craft a range of parts from full lengths of both mild and stainless steel.

This attention to detail guarantees that every Flamery grill emerges from the fusion of innovation and craftsmanship, resulting in a cooking experience that truly stands out.

Folding

After the laser cutting process, the sheet components undergo shaping into 3D forms using a press brake. This involves bending the components to predetermined angles by clamping the workpiece between a matching top tool and bottom die.

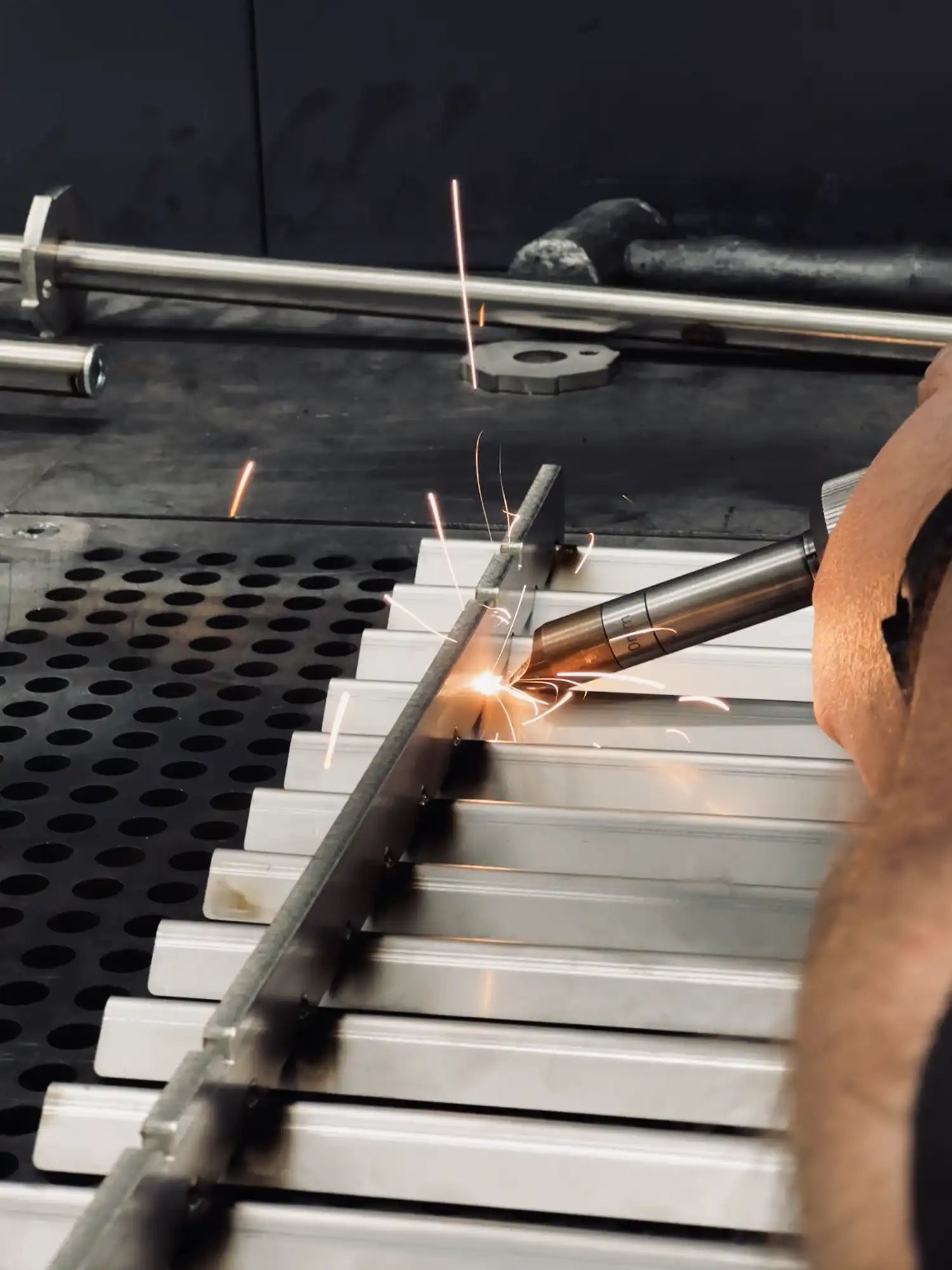

Welding

Our factory houses an impressive welding department staffed with skilled craftspeople proficient in various welding methods.

Our stainless steel parts undergo fibre laser welding, leveraging laser beams' power and concentrated heat to melt the materials, which then fuse together upon cooling.

For non-stainless steel parts, we employ the traditional method of MIG welding. This involves a constant voltage power supply creating an electric arc that fuses the base metal with a continuously fed filler wire through the welding torch. Simultaneously, an inert shielding gas is fed through the gun to protect the weld pool from atmospheric contamination.

After welding parts are put through a process called linishing, this process uses a grinder to improve the flatness, smoothness and uniformity of the surface, giving a better more uniform finish.

Powder Coating

After welding, all non-stainless parts undergo powder coating using a specialised high-temperature paint. This paint is specifically formulated for BBQs and stoves, offering corrosion protection and maintaining appearance integrity for our components.

Everything else...

We take a very can do attitude here at Flamery, and luckily have a huge amount of expertise and experience in our factory to draw upon. When the branded crest that adorns the BBQs and stands came up for discussion, the usual approach might have been to outsource this work and buy the parts in. But not here... we embraced the challenge and set to designing our own stamp and die set to use in one of our press brakes.

A little trial and error, and rather a lot of tonnage later, and the stamp was happily being pressed in our factory!

Assembly & Delivery

Finally, our packing team ensures that all customer orders are securely packed and protected for transit.

With a manufacturing background, we have the logistics experience to distribute products efficiently. We are confident that with our logistics partners, every shipment will arrive undamaged, on time, and in full, every time.